EOAT (End of Arm Tool)

We supply bespoke EOAT solutions are designed for durability and long term reliability, creating robust tools that withstand the demands of rigorous industrial use.

We design and supply bespoke End of Arm Tooling (EOAT) solutions tailored to meet the demands of modern requirements in manufacturing.

Our tooling is engineered to suit each application, whether it’s pick and place, packing, palletising or handling delicate or irregular items. We work closely with clients in sectors including food and beverage, pharmaceuticals, manufacturing, and logistics, ensuring every tool is manufactured for its task to the highest standards.

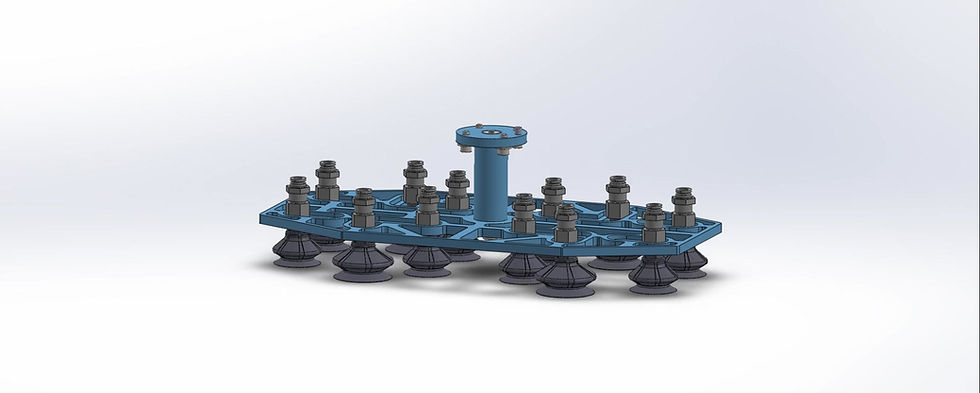

From vacuum grippers to complex multi function heads, our tooling is built for durability and performance. Using well tried and tested components and robust design principles, we provide reliable solutions that help maximise robotic capability and reduce downtime, all backed by expert support.

Dual Purpose

We enable robots to perform multiple functions with a single tool for a range of tasks, including palletising, handling pallets and picking layer pads. By incorporating flexible grippers, we maximise the productivity and utility of your robotic systems, ensuring that your investment delivers a higher return.

Cobot

Our cobot EOAT is designed with both safety and functionality in mind, making them ideal for applications where humans and robots work closely with one another. Equipped with high visibility protection, our grippers not only maximise safety but also reduce the risk of accidental damage to products or equipment.

Welding

Our welding tooling is developed to deliver precise, consistent results in demanding production environments. Whether it’s for MIG, TIG, spot or Laser welding, we engineer fixtures and jigs that ensure accurate alignment, secure part holding and repeatable weld quality.

Sack Handling

We produce sack gripping solutions for palletising and depalletising, designed to handle a wide range of bagged products with speed and reliability. Whether dealing with paper, plastic or woven sacks, our grippers provide secure handling without damaging the product.

End of Arm Tool Changers

At Rise Automation, we offer tool changer solutions that give your systems the flexibility to switch between different tools automatically or manually. This means one robot can carry out multiple tasks in a single automation solution. Tool changers are a smart way to increase efficiency and make better use of space, especially in production environments handling a mix of products or varying tasks.

Pneumatic Tool Changers

Pneumatic systems use compressed air to lock and release tools quickly. They’re ideal for fast, fully automated setups where a robot needs to switch tools regularly without stopping the process, or where the tooling is too heavy for manual changeovers.

Mechanical Tool Changers

Mechanical tool changers operate using simple locking mechanisms, typically without the need for external air or power. They offer a robust and cost effective solution for general purpose tasks, where tool changes are less frequent but still need to be secure and repeatable.

Bespoke End of Arm Tooling

Every EOAT solution begins with a thorough discovery phase, where we take time to understand your product, process, and handling challenges. We review samples, assess weight, shape, surface, and material, then identify key functional requirements such as gripping method, orientation, and cycle time. Working closely with your team, we develop detailed 3D models for review and approval, ensuring every detail is aligned before manufacture, so the final tool performs exactly as expected.

End of Arm Tooling we Offer

Vacuum Grippers

Ideal for picking flat or smooth items such as boxes, trays, or sheets. Commonly used in logistics, packaging and food processing.

Pallet Grippers

Grip pallets during stacking or destacking for integrated with palletising systems.

Parallel Grippers

Fingers move in parallel to grip suited for uniform, rigid objects such as machined parts or small containers.

Sack Grippers

Securely handle bagged products for palletising and depalletising. Suited to industries like agriculture, animal feed, and bulk food production.

Foam Grippers

Offer adaptable gripping for irregular or fragile items, ideal for food, cosmetics and electronics packaging.

Magnetic Grippers

Use magnets to lift metal items effective in metal fabrication, welding, and automotive assembly.

Mechanical Grippers

Versatile gripping for solid objects of various shapes and sizes, used in manufacturing, assembly, and warehousing.

Multi function Grippers

Combine tasks such as picking products, placing layer pads, and handling pallets. Used in end of line automation across multiple sectors.

Soft Grippers

Made from flexible materials to gently grip delicate or deformable items such as food products like fruit, baked goods, or oddly shaped items.

Needle Grippers

Designed to grip soft or porous materials such as textiles or foam. Common in textile production and automotive interiors.

Rotating or Tilting Heads

Enable orientation changes during handling, useful in assembly lines, machining operations, and packaging.

Plate Grippers

Clamp products using flat plates from both sides for handling heavy cartons, or products where suction isn’t reliable.

Tool Changers

Allow robots to switch between different EOATs automatically, boosting flexibility in mixed product or multi process environments.

FAQs

What is End of Arm Tooling (EOAT)? EOAT, or End of Arm Tooling, refers to the device or tool attached to the end of a robotic arm, allowing the robot to interact with objects. Common EOAT types include grippers, suction cups, welders, and vision systems.

Why is EOAT important in automation? EOAT is essential for enabling robots to perform specific tasks like picking, gripping, cutting, welding, or inspecting. The right tooling increases efficiency, precision, and adaptability in industrial processes.

What types of EOAT do you supply? We supply a wide range of EOAT including vacuum grippers, pneumatic grippers, magnetic grippers, welding torches, vision sensors, and custom tool changers.

Can EOAT be customised for specific applications? Yes. We offer fully customised EOAT solutions designed around your application requirements, product dimensions, and production speed.

What industries benefit from EOAT solutions? EOAT is widely used in sectors like automotive, electronics, food & beverage, pharmaceuticals, logistics, and metal fabrication.

What’s the difference between mechanical and vacuum grippers? Mechanical grippers use fingers or claws to grip objects, while vacuum grippers use suction force. Choice depends on the object's shape, material, and fragility.

How do I choose the right EOAT for my robot? Factors to consider include payload, object material, precision requirements, speed, and the task (e.g. welding vs. pick and place).

Is EOAT compatible with refurbished robots? Absolutely. We match EOAT to both new and refurbished robots, ensuring seamless integration and optimal performance.

Can EOAT be interchanged between tasks? Yes, using automatic or manual tool changers, robots can switch EOAT to perform multiple tasks in one cycle or shift.

Do you offer EOAT for collaborative robots (cobots)? Yes. We supply lightweight, safe EOAT for cobots, designed to meet collaborative safety standards while maximising flexibility.

What are robotic grippers used for? Robotic grippers are used to grasp, hold, and manipulate parts. They're common in pick-and-place tasks, packaging, assembly, and material handling.

Can I retrofit EOAT to an existing robot? Yes. We provide retrofit EOAT solutions, including mounting plates, adapters, and interface control, for a wide range of robot arms.

Do you provide EOAT installation and programming support? We offer full integration services, including EOAT mounting, I/O setup, software configuration, and cycle testing.

What materials can EOAT handle? With the right tooling, EOAT can handle anything from delicate food products to heavy metal parts, glass, electronics, and irregular objects.

Is EOAT energy efficient? Modern EOAT solutions are designed for energy efficiency, with lightweight materials, optimised pneumatic usage, and smart controls.

Can EOAT include sensors or vision systems? Yes. We integrate vision-guided EOAT with 2D/3D cameras, force sensors, and feedback loops to enhance accuracy and adaptability.

What’s a tool changer in robotic EOAT? A tool changer allows a robot to automatically or manually switch between different EOATs, enabling multi-task automation with a single robot.

Do you supply spare parts for EOAT systems? We stock a full range of EOAT components, replacement parts, and consumables to minimise downtime and keep your operations running smoothly.